10 Best Laser Engraving Woods 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

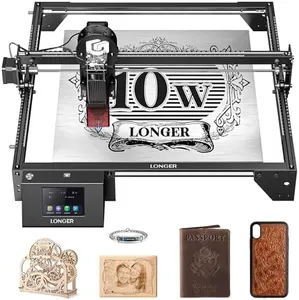

LONGER Laser Engraver Ray5 10W, 60W DIY Laser Cutter and Laser Engraving Machine with 3.5" Touch Screen,0.06mm Laser Spot 10000mm/min, Offline Usage CNC Laser Engravers for Wood Metal Acrylic Glass

Most important from

301 reviews

The LONGER Ray5 10W laser engraver offers impressive laser power with its 10W output, making it suitable for wood and other materials like metal, acrylic, and glass. The large engraving area of 400x400mm provides ample space for various projects, accommodating larger designs. Its high resolution with an ultra-fine laser point of 0.06mm and precision of 0.01mm ensures detailed and accurate engravings.

The machine boasts a rapid speed of up to 10,000mm/min, enhancing productivity for users working on multiple projects. The versatility in connectivity options—USB, TF card, WiFi, and app support—paired with compatibility with popular software like LaserGRBL and LightBurn, makes it user-friendly for different tech preferences and workflows.

Safety is a priority, with features like emergency stop, motion protection, heat protection, and cooling system, extending the laser's lifespan and ensuring user safety. However, the machine's weight of 9.63 pounds might be a concern for those looking for a lightweight, portable option. Additionally, while it supports offline usage, users must ensure they have the necessary technical know-how to operate it efficiently.

Most important from

301 reviews

LONGER Laser Engraver Ray5 5W Higher Accuracy DIY Laser Engraving Machine with 3.5" Touch Screen,Offline Usage Laser Cutter,400x400mm,0.08mm Laser Spot, CNC Laser Cutter for Wood Metal Acrylic Glass

Most important from

301 reviews

The LONGER Laser Engraver Ray5 5W is a versatile and high-performing machine well-suited for wood engraving tasks. With a laser power of 5W, it delivers precise cuts and engravings, boasting a very fine laser spot size of 0.08mm. The engraving accuracy is impressive at 0.01mm, which allows for intricate designs and detailed patterns. The large 400x400mm engraving area provides ample space for various project sizes, enabling users to work on a wide range of tasks without needing to reposition materials frequently.

The machine's speed is a standout feature, reaching up to 10,000mm/min due to its advanced 240MHz ESP32 chipset. This high processing power also ensures good energy efficiency and compatibility with multiple software options like LaserGRBL and LightBurn, offering flexibility to users with different preferences. Connectivity options are varied, including USB, TF card, WiFi, and app connections, facilitating offline use and convenience. Safety features are robust, with emergency shutdown, motion protection, and overheating prevention mechanisms, along with protective gear such as covers and goggles.

Material compatibility is a significant strength, handling not only wood but also stainless steel, leather, metal, glass, and acrylic. This makes it a versatile tool for creative projects across different materials. The product comes with easy installation tools and 24/7 support, making it accessible even for beginners. This engraver suits hobbyists and small business owners looking for precision and versatility in their engraving projects.

Most important from

301 reviews

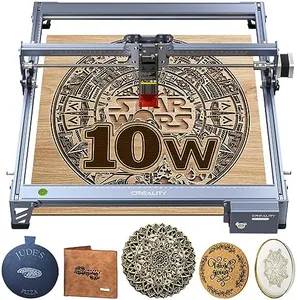

LaserPecker LP4 Ultimate Bundle with Desktop Air Purifier, Dual-Laser Engraver & Cutter 160x300mm Workspace, Auto-Cleaning for Smoke/Fumes, Engrave Metal/Wood/Plastic, with Slide & Rotary Extensions

Most important from

173 reviews

The LaserPecker LP4 Laser Engraver Ultimate Bundle is designed for those who need a versatile and efficient engraving solution. One of its biggest strengths is the dual laser system (Infrared and Diode), which makes it flexible for working with various materials, including wood, metal, acrylic, leather, and more. This covers a broad range of crafting needs and offers robust material compatibility.

The bundle includes useful accessories like an air purifier, slide extension, and rotary extension, which enhance its functionality and make it suitable for batch processing, a valuable feature for small business owners or hobbyists with high output requirements. The air purifier ensures a healthier and cleaner workspace, although it might add to the weight and space needs of the setup (41.6 pounds and dimensions of 32.28 x 12.01 x 16.54 inches). The engraving area and speed offer flexibility with adjustable angles, allowing for creative freedom with various object shapes and sizes.

The software compatibility is a highlight, offering ease of use through smartphone and PC applications, and advanced functionalities with Lightburn. Though the initial setup might be more complex due to its multifunctionality, the user-friendly apps and tutorials can help overcome this learning curve. The product is relatively new (available from April 2024), and comes with a 1-year warranty, adding some assurance for buyers. The extensive feature set and included accessories suggest it might be a higher-end option. This laser engraver is best suited for users who need a versatile, capable machine for a variety of materials and are willing to invest in a comprehensive tool for their crafting or small business needs.