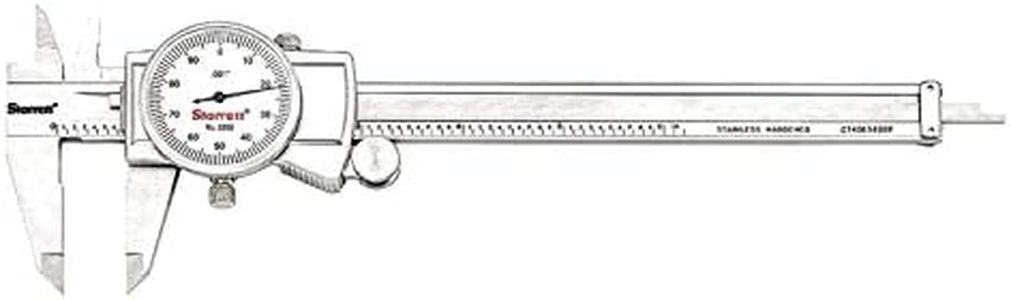

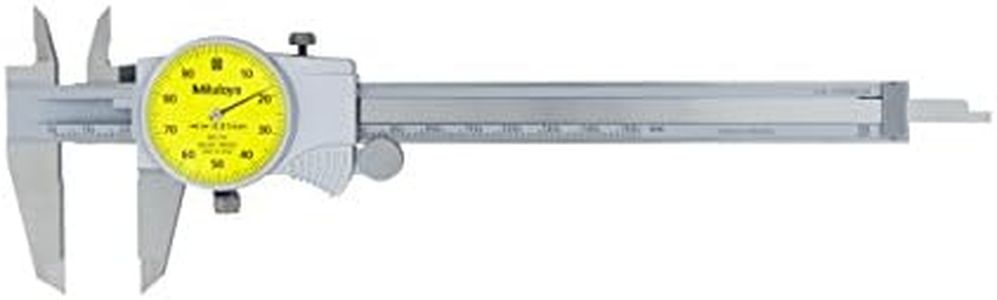

Buying Guide for the Best Dial Calipers

Dial calipers are precision measuring tools used to measure the dimensions of an object with high accuracy. They are commonly used in various fields such as machining, metalworking, and woodworking. When choosing a dial caliper, it's important to consider several key specifications to ensure you select the best tool for your needs. Understanding these specifications will help you make an informed decision and get the most out of your purchase.Measurement RangeThe measurement range of a dial caliper indicates the maximum length it can measure. This is important because it determines the size of the objects you can measure with the caliper. Common ranges include 0-6 inches, 0-8 inches, and 0-12 inches. If you typically work with smaller objects, a 0-6 inch caliper may be sufficient. For larger objects, consider a caliper with a greater range. Choose a range that matches the typical size of the items you measure to ensure versatility and convenience.

AccuracyAccuracy refers to how close the caliper's measurements are to the actual dimensions of the object. This is crucial for tasks that require precise measurements. Accuracy is usually expressed in thousandths of an inch (e.g., ±0.001 inches). Higher accuracy is essential for precision work, such as in machining or quality control. For general use, a standard accuracy of ±0.001 inches is often sufficient. If your work demands extremely precise measurements, look for calipers with higher accuracy.

Dial ResolutionDial resolution is the smallest increment that the caliper's dial can display. It determines how finely you can read the measurements. Common resolutions include 0.001 inches and 0.0005 inches. A finer resolution allows for more detailed measurements, which is important for high-precision tasks. For general purposes, a resolution of 0.001 inches is usually adequate. If you need to measure very small differences, opt for a caliper with a finer resolution.

MaterialThe material of the caliper affects its durability and longevity. Common materials include stainless steel and carbon fiber. Stainless steel calipers are highly durable and resistant to corrosion, making them suitable for heavy-duty use. Carbon fiber calipers are lighter and less prone to damage from drops, but they may not be as durable as stainless steel. Choose a material based on your working environment and how you plan to use the caliper. For rugged use, stainless steel is a good choice, while carbon fiber is ideal for lighter tasks.

Ease of UseEase of use encompasses features that make the caliper user-friendly, such as a smooth sliding mechanism, clear dial markings, and a comfortable grip. These features are important because they affect how efficiently and accurately you can take measurements. Look for calipers with a well-designed dial that is easy to read and a sliding mechanism that moves smoothly without sticking. A comfortable grip can also reduce hand fatigue during extended use. Consider your comfort and the ease with which you can read and adjust the caliper when making your choice.

Additional FeaturesSome dial calipers come with additional features such as a depth gauge, step measurement capability, or a locking screw. These features can enhance the versatility and functionality of the caliper. A depth gauge allows you to measure the depth of holes, while step measurement capability lets you measure the distance between steps or ledges. A locking screw can hold the jaws in place for consistent measurements. Consider what additional features might be useful for your specific tasks and choose a caliper that includes those features.